Production processes perform through separator machines to remove contaminants according to the standard. Then go to cracker machines to get the unpolished rice (Brown rice). In the separation process, we are confidence in using modern machines to get high quality brown rice, clean, and without contaminants..

Brown rice passes to polishing white machine to remove rice bran layer from the brown rice to get the white rice which still retains value nutrition as well as the taste of rice for consumer health benefits. In another word, the rice’s nutritional value and benefits perfectly retained.

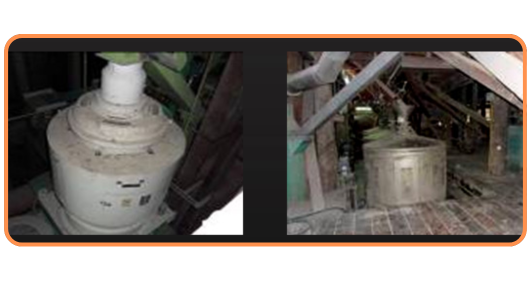

The white rice passes into the rice polishing machine to get the rice white and shiny, nice rice grains with the same size of grains as the market needs. This process will retain the product quality which allows the product can be kept longer.

Process the white rice through the color separating machine; this is controlled by a computer system which identifies and separates the perfect rice from the imperfections. In this process, the machine will sort out the waste grain, red and yellow grains, including rice grain that is controlled under quality standards. To get white rice grains within quality standards of premium rice exporting laws.

Our rice is stored in silos and warehouses that meet the finest international standards of hygiene and cleanliness. We ensure quality control for sanitation and weight by using a closed system for packaging; this automated system eliminates contamination and guarantees that the consumer receives exactly what is ordered: pure, fresh, and fragrant Thai rice. Our products are available in vacuum-packed containers for weights from one to eight (1 – 8) kilos and in traditional packaging for weights from five to 100 (5 – 100) kilos.